|

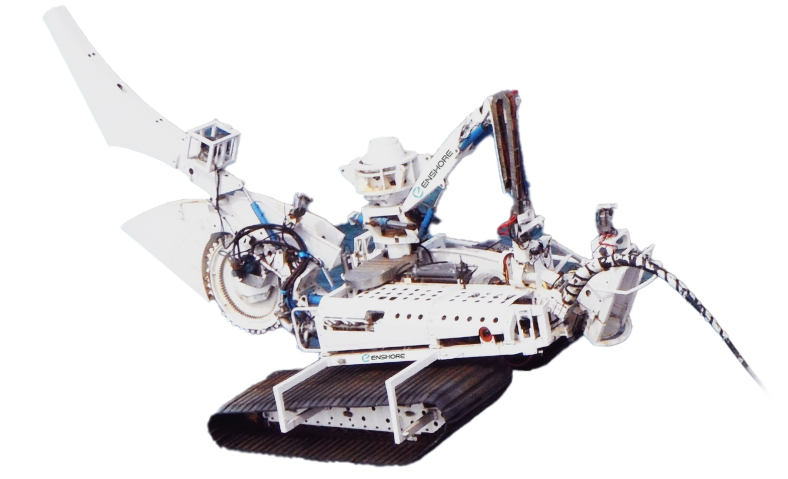

ENSHORE T1 OVERVIEW

|

|

|

Wheel Cutter |

JETTER |

|

Operating Depth |

1000m |

1000m |

|

Max. Product Diameter |

250mm |

500mm |

|

Max. Trench Depth |

1.3m |

2.0m |

|

Length |

13m |

11.5m |

|

Width |

5.5m |

5.5m |

|

Height |

6.5m |

6.5m |

|

Weight in Air |

25te |

19.5te |

|

Weight in Water |

16te |

12te |

|

SPEED RANGE

|

|

No Burial |

0 -1500m/hr |

|

Trenching with Cutter Chain |

50 - 250m/hr |

50 - 500m/hr |

|

VEHICLE POWER

|

|

520W (2 x 260kW) electric motor supply main vehicle hydraulics and 2 fixed / variable speed drives and water supply |

|

SOIL TYPES

|

|

Wheel Cutter |

Suitable for all sands, soft to hard clays and weak rock |

|

Jetter |

Suitable for all uncemented sands, and soft to firm clays |

|

PRODUCT HANDLING

|

|

Wheel Cutter |

Product is carried from the front mounted bell-mouth over the top of the vehicle, through trough assembly, to wheel cutter. Bellmouth fitted with feeler assembly to assist in monitoring cable catenary during simultaneous lay-trench operations. |

|

Jetter |

Product passes underneath Trencher between tracks before passing through jet legs into fluidised trench. Bellmouth fitted with feeler assembly to assist in monitoring cable catenary during simultaneous lay/trench operations. Depressor can be fitted between jet legs to ensure positive depth location when trenching flexible products. |

|

WHEEL CUTTER

|

|

Cutter |

Wheel type mechanical cutter with depressor assembly and enclosed cable handling system mounted on rear instrumented tool linkage |

|

Flow Rate |

437m3/hr @ 4.6 bar |

|

Trench Width |

Up to 390mm |

|

Wheel Type |

External spur gear transmission |

|

Cutting Picks |

37.5mm diameter Tungsten Carbide point attack cutting picks |

|

Wheel Speed |

Up to 50RPM |

|

JET TOOL

|

|

Gap Between Legs |

200-500mm maximum |

|

Flow Rate |

1748m3/hour at 4.6 bar |

|

Forward Jet Tool |

Not product engaging, suitable for tight turns, loops, close proximity etc. |

|

Cutting Picks |

5mm diameter Tungsten Carbide point attack cutting picks |

|

CRANE MANIPULATOR

|

|

Maximum Load |

2000kg |

|

Maximum Reach |

7m |

|

8 functions total + boom mounted camera for peripheral vision |

|

SURVEILLANCE EQUIPMENT

|

|

Obstacle Avoidance Sonar |

|

6 x Subsea Cameras |

|

2 x Pan & Tilt Units |

|

1 x Rotator Unit |

|

8 x Subsea Lights |

|

Responder / Transponder |

|

Mini F.O.G Gyro |

|

2 x 720i Gemini Sonar |